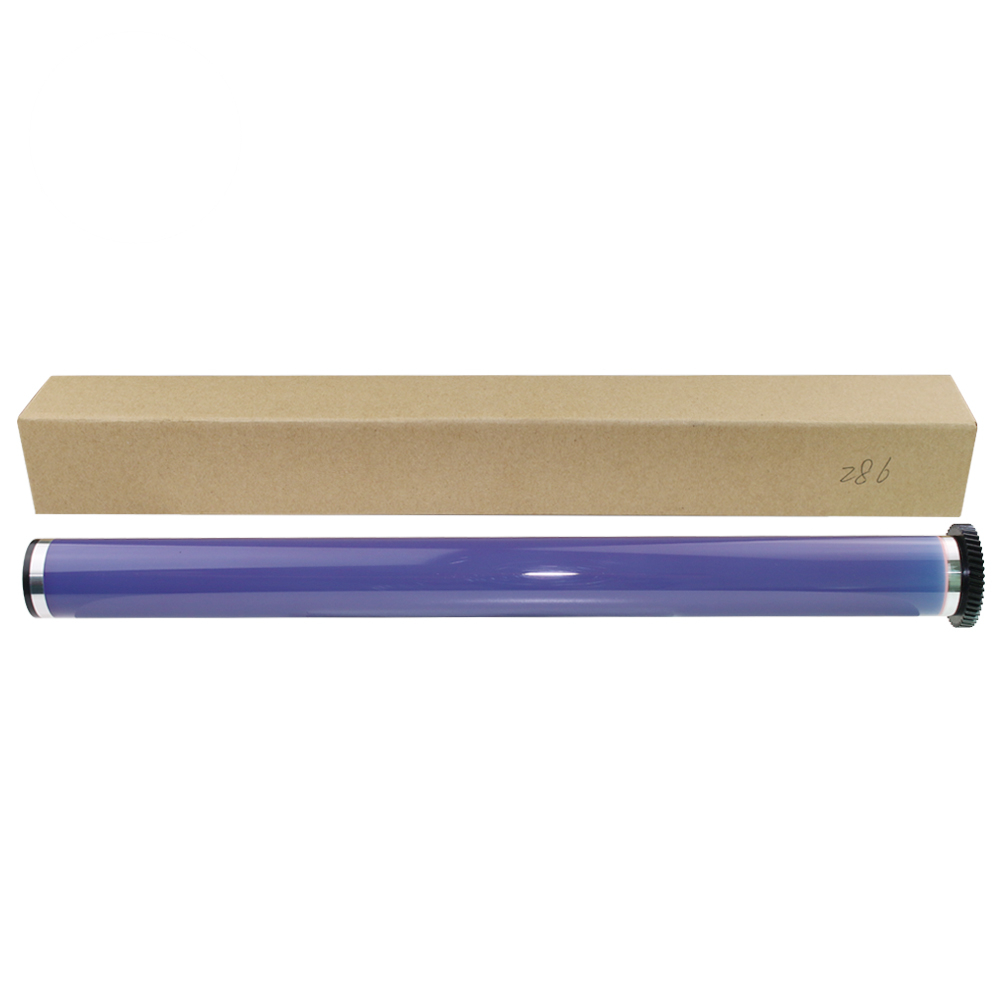

This product is suitable for Xerox DC240/242/250/252/550/650/750/5000 DocuCentre-C5065/5540/6075/6550, thick OPC coating, supports 100,000 pages print yield, and is durable. Good print quality, clear and no ghosting, environmentally friendly materials.

Our products are exported to the United States, Europe, Middle East, Africa, Asia and other countries.

█ Material Environmental Protection

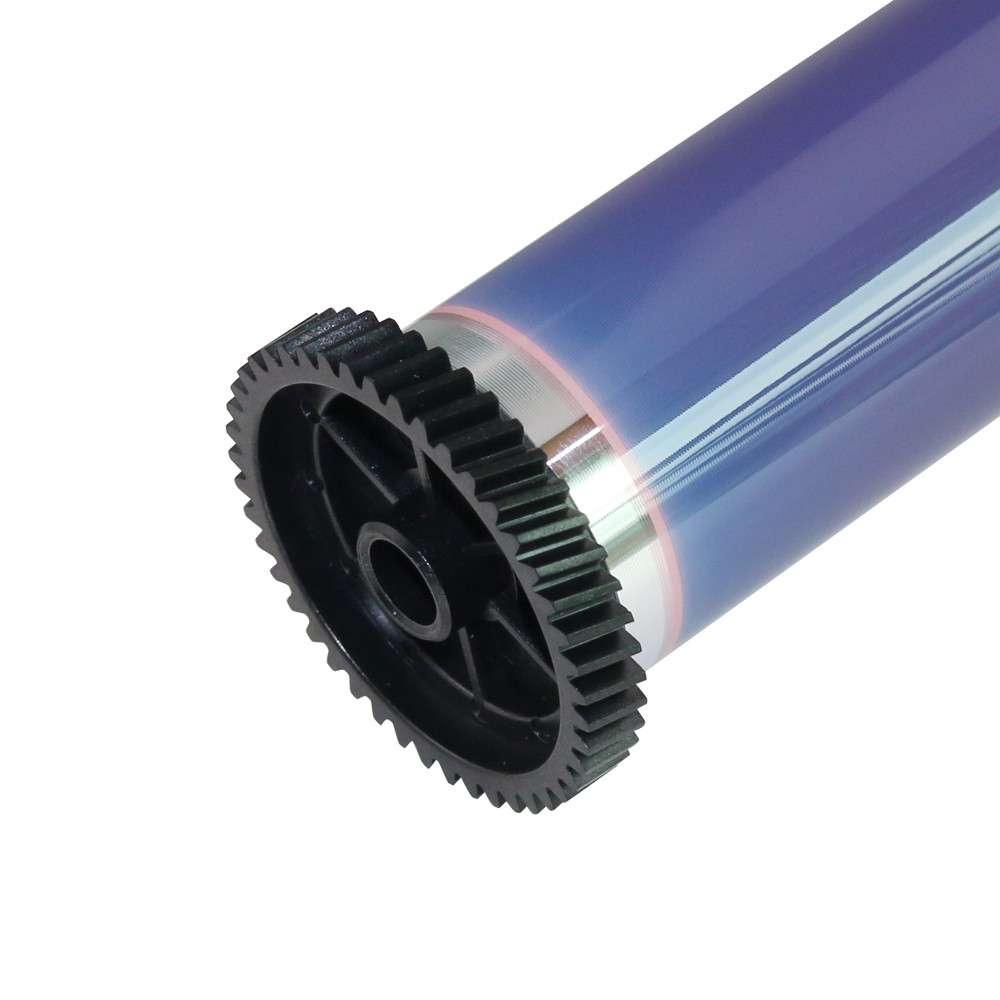

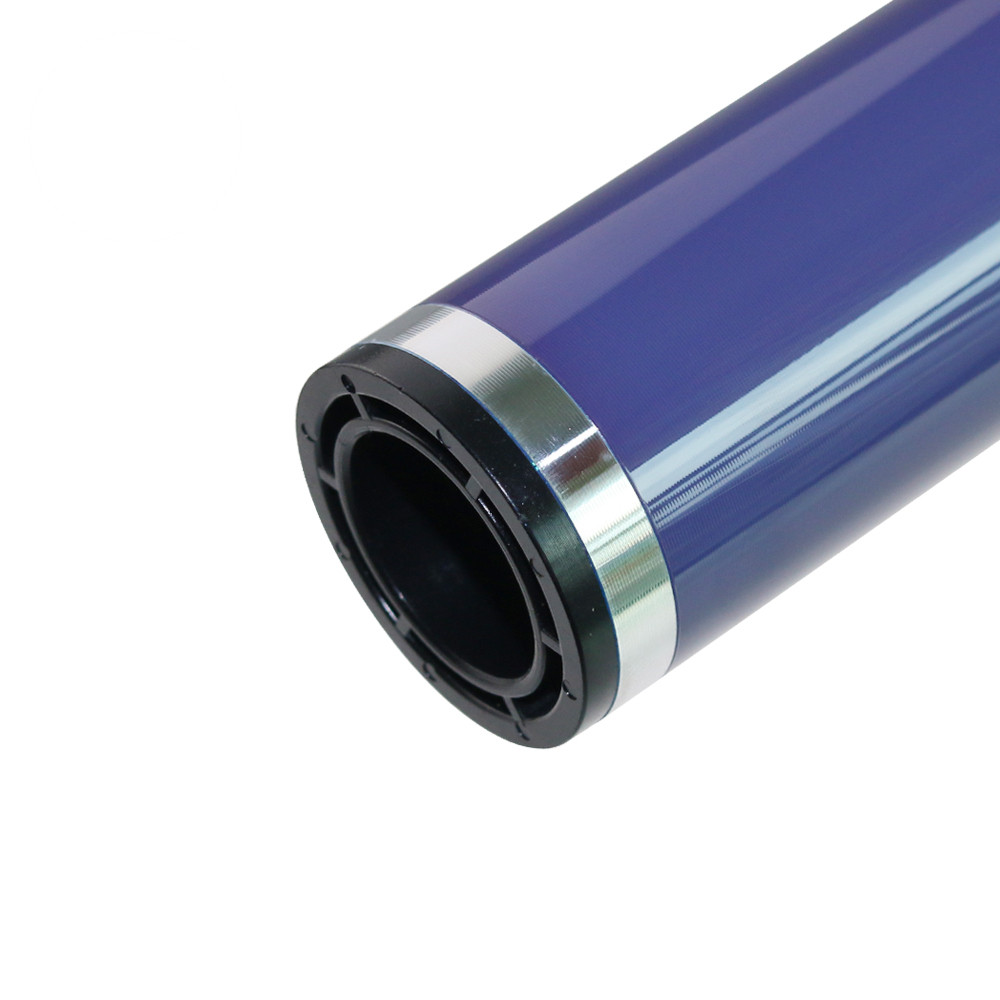

█ Exquisite Craftsmanship, Complete Model

█ Pay Attention To Details, Keep Improving

█ 15 Years Brand, Guaranteed Quality

█ Factory Competitive Price

█ Not To Hurt The Machine

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved