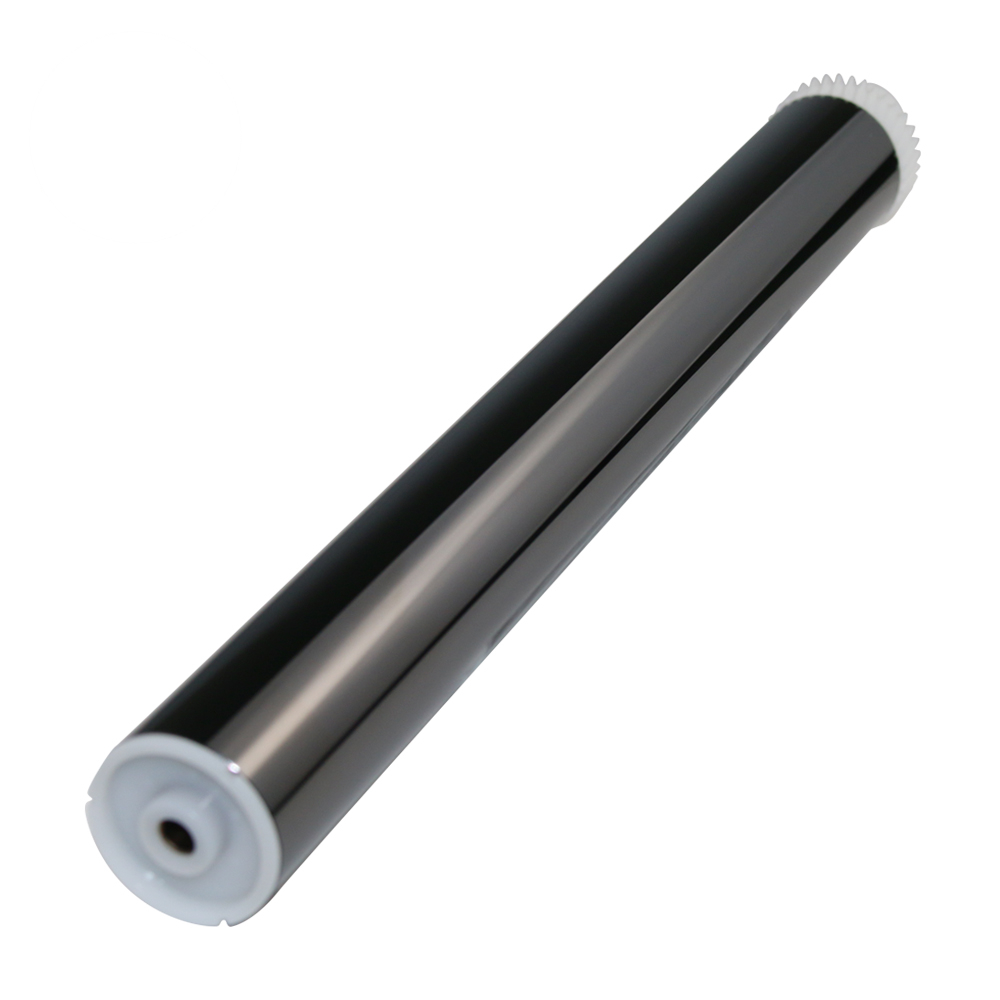

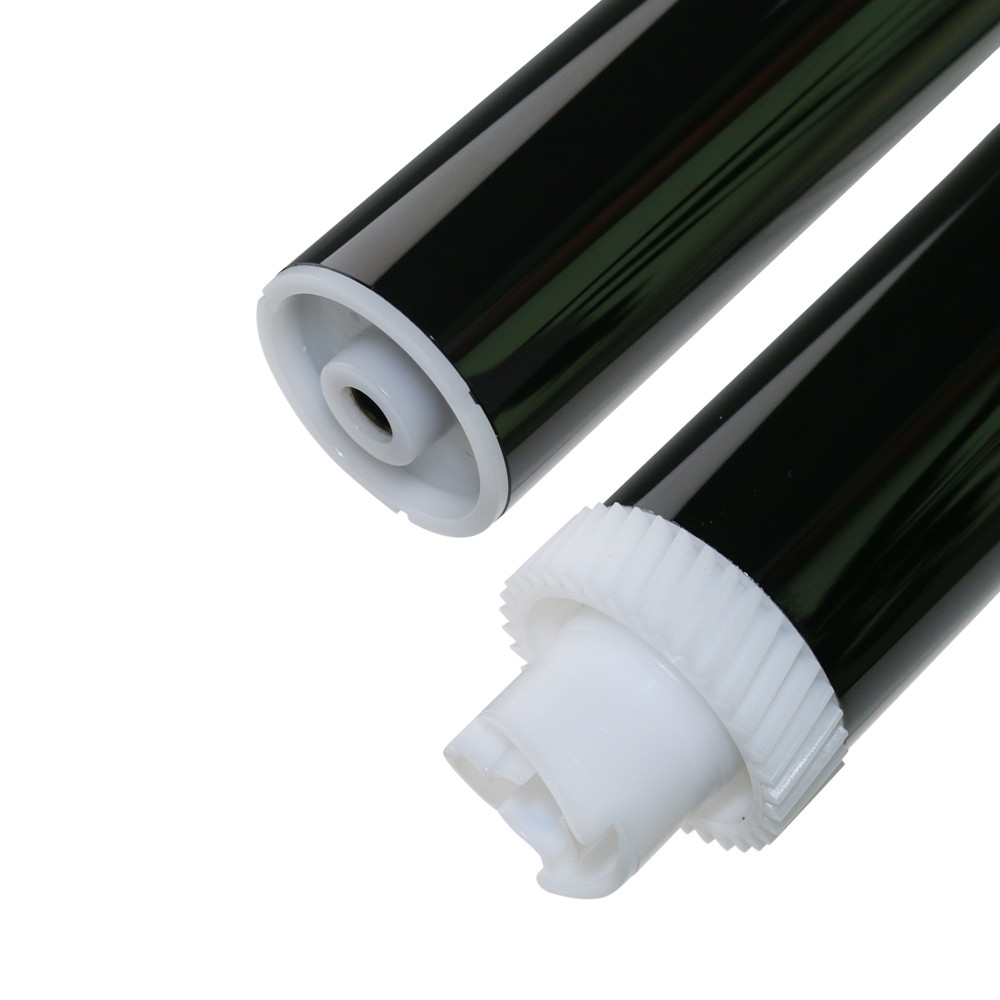

This black OPC drum is for Kyocera FS2100 4100 4200 4300/M3040 3540 3550 3560, which is easy to use, ready to use and long lasting. Our product models are complete, and the range of accessories is complete, we will provide you with a one-stop consumable service.

█ Material Environmental Protection

█ Exquisite Craftsmanship, Complete Model

█ Pay Attention To Details, Keep Improving

█ 15 Years Brand, Guaranteed Quality

█ Factory Competitive Price

█ Not To Hurt The Machine

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved