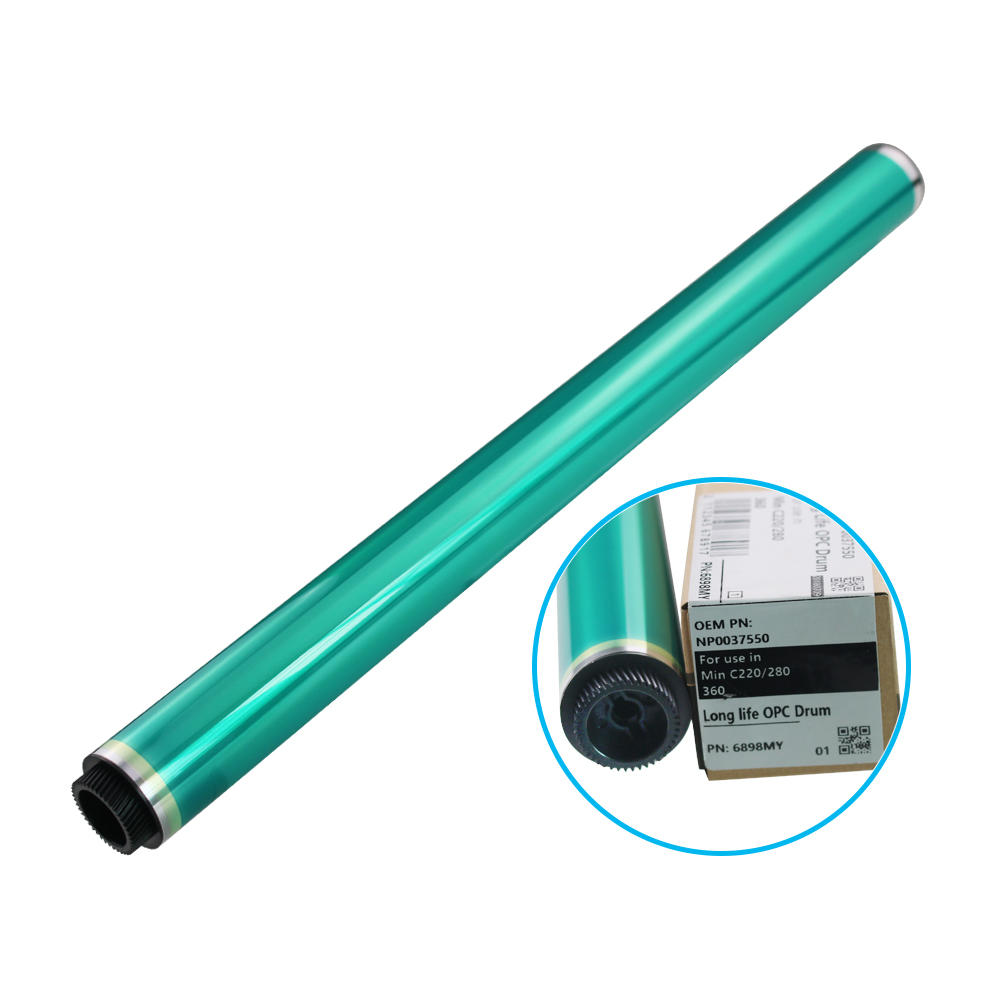

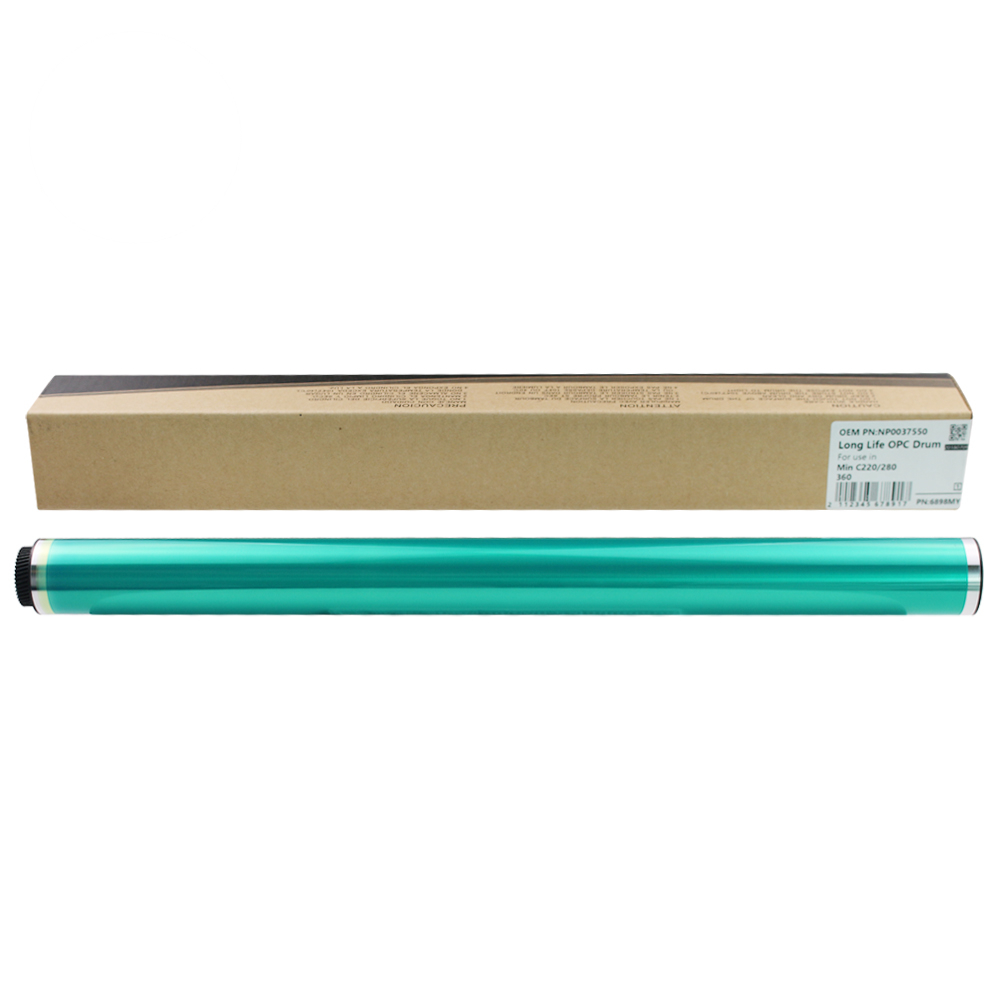

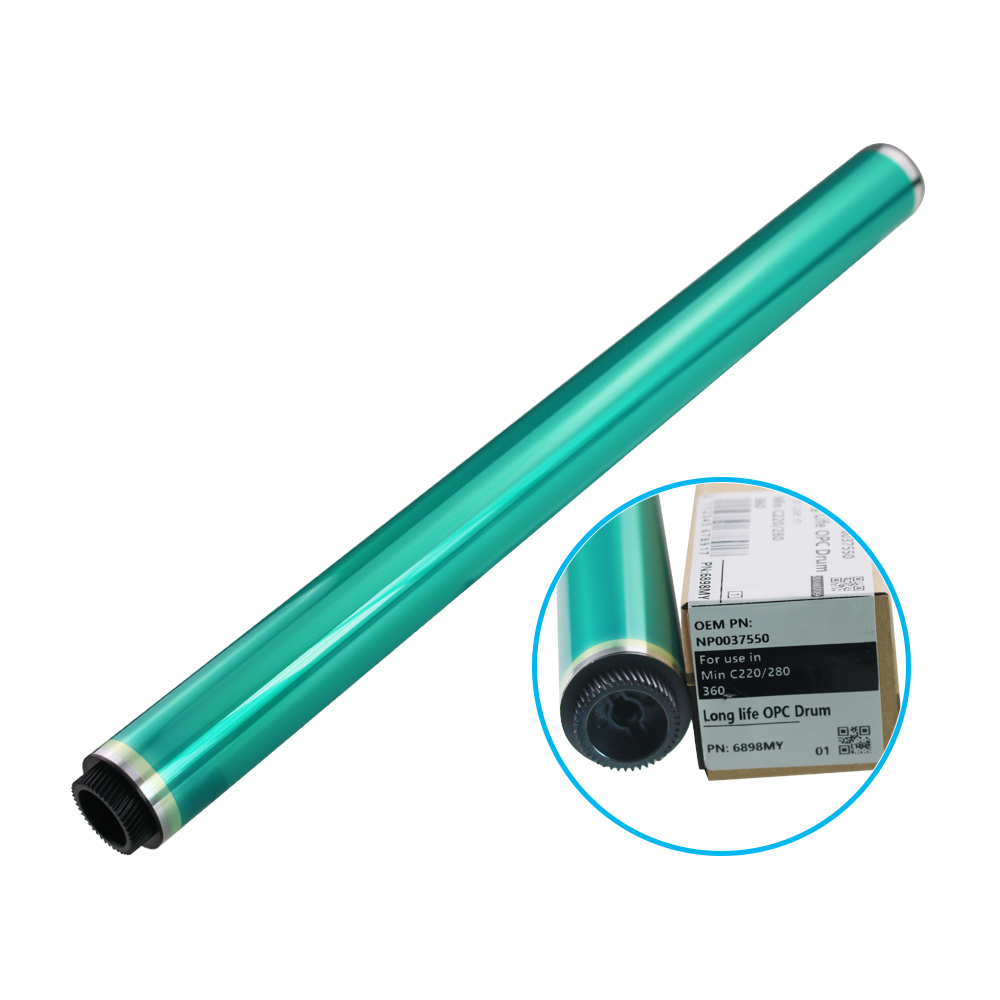

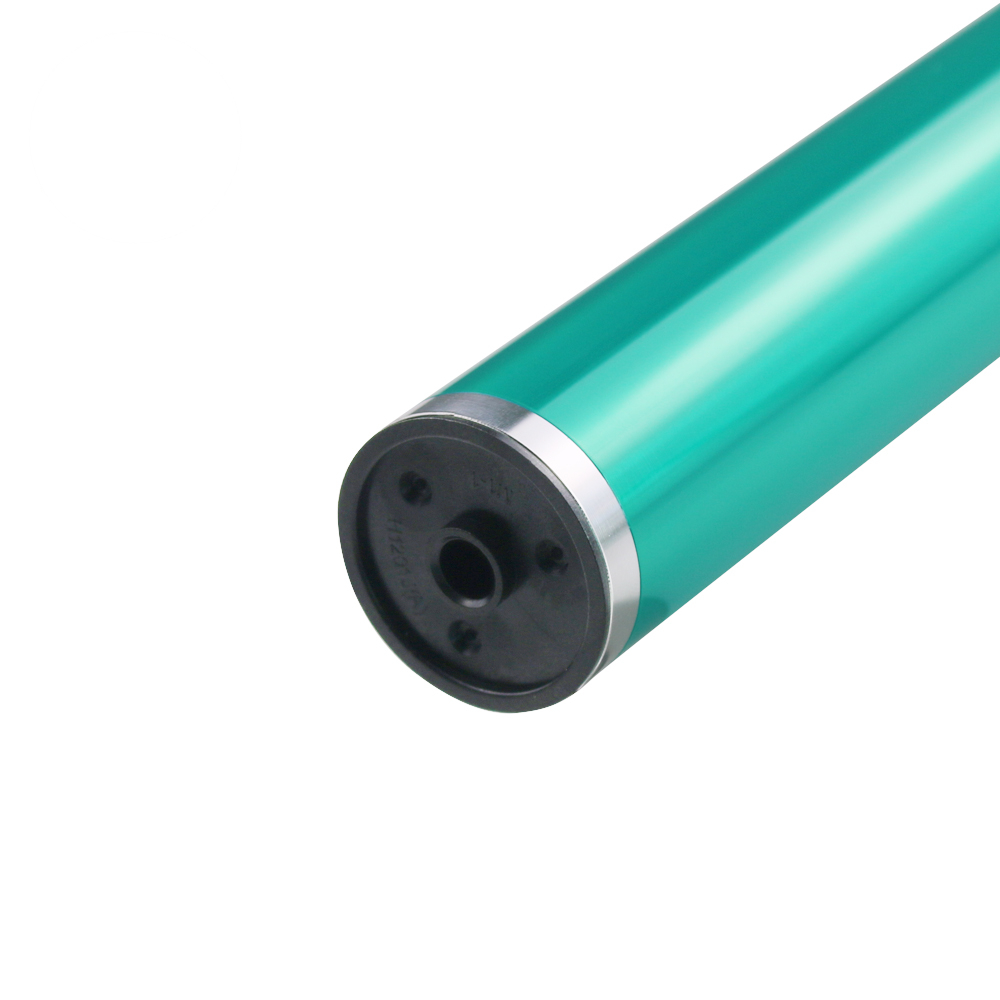

This product is suitable for Konica Minolta Bizhub C220/280/360(DR-413)/224. Due to its strong compatibility, excellent quality, clear printing, easy to use and durable, it is the first choice for enterprise and company copier consumables.

We are a brand supplier and manufacturer with 15 years of experience, providing a full range of consumable products for all models. Kraise, your one-stop sourcing service partner.

█ Material Environmental Protection

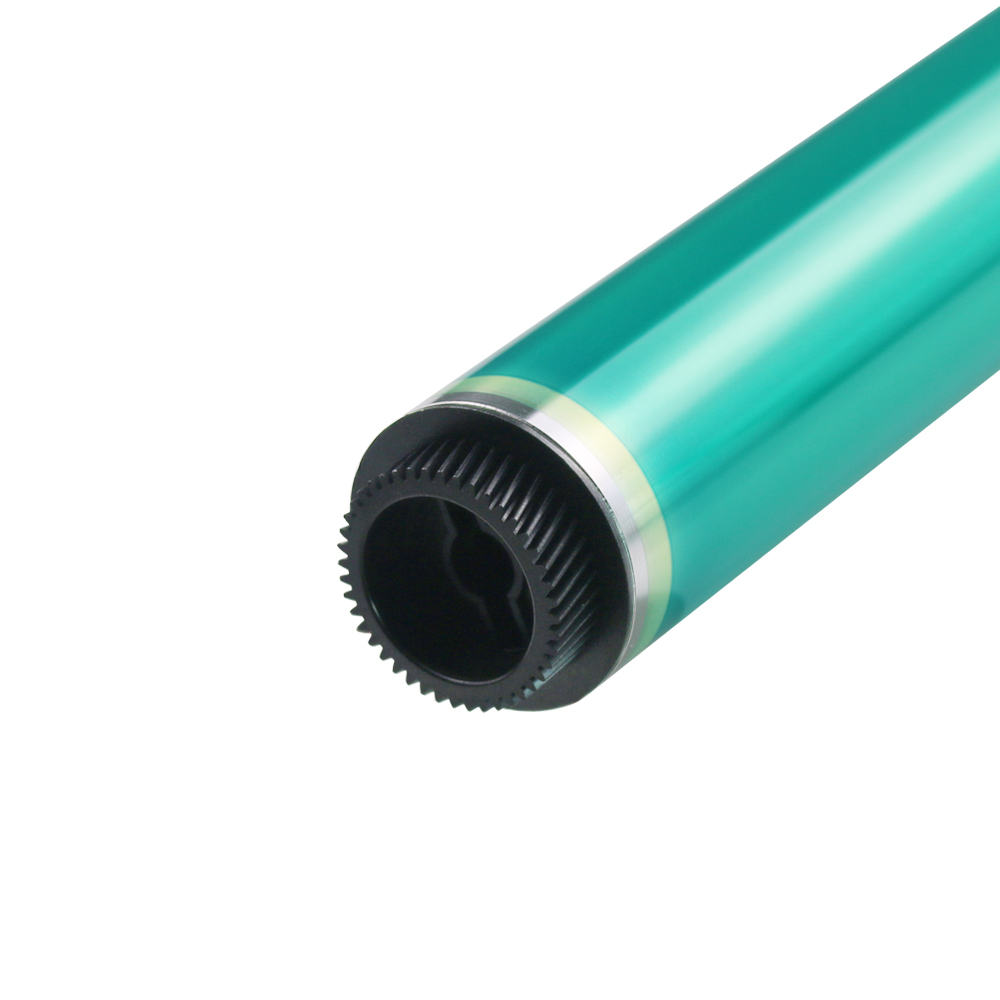

█ Exquisite Craftsmanship, Complete Model

█ Pay Attention To Details, Keep Improving

█ 15 Years Brand, Guaranteed Quality

█ Factory Competitive Price

█ Not To Hurt The Machine

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved