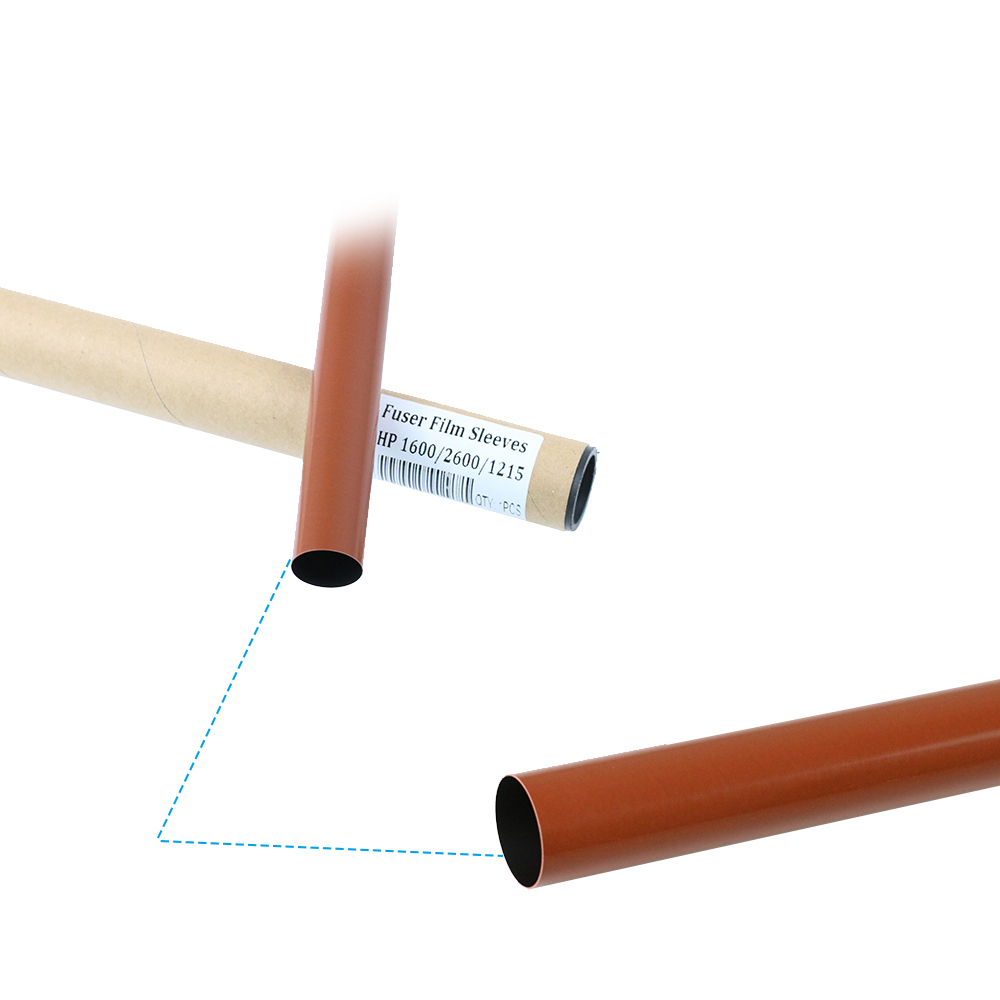

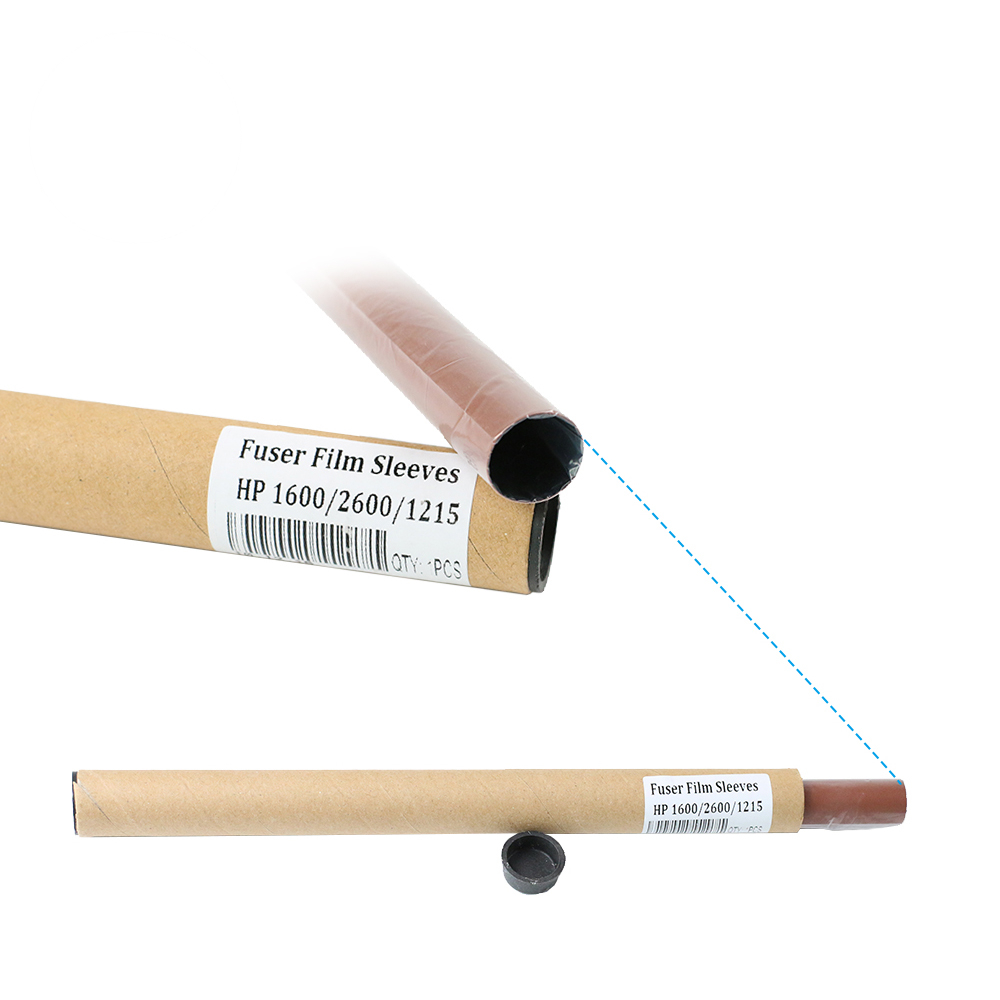

This fuser film sleeve is suitable for HP1600/1605/2600/2605/CP2025/CM2320/ M375/M475/M277/M275/M276/ Multifunction Color CM1015/CM1017mfp. Our products sell well in Europe, the United States, the Middle East and Asia, and have won the love and trust of consumers. It is a well-known printing consumable brand in China.

█ 15 Years Brand, Guaranteed Quality

█ NO.1 Fuser Film Factory In China

█ One-stop Shopping, Saving Time And Budget

█ Strictly Quality Control System

█ Provide the sample, Accept Customization

█ Complete Range Of Consumable Parts

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved