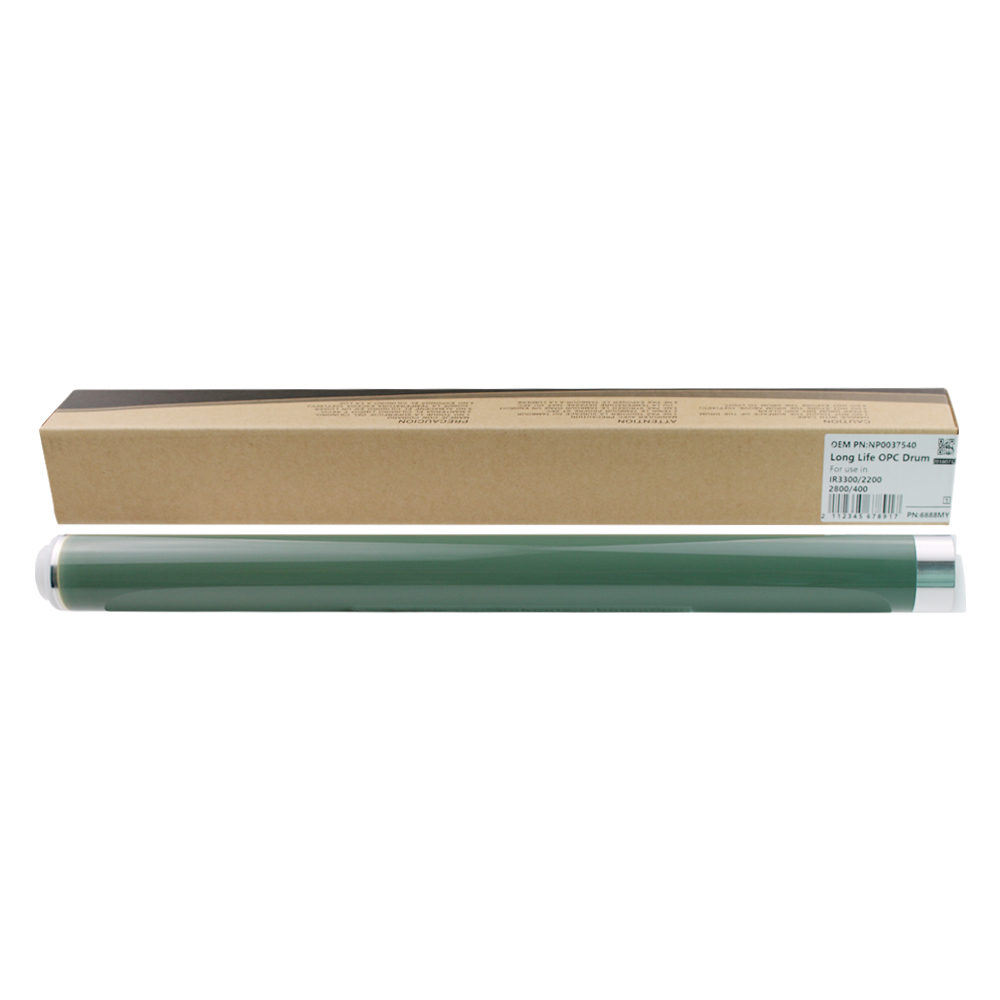

This green OPC drum is suitable for Canon IR 3300/2200/2800/IR330/400/GP-200/210/215/300/335/400/405. The product has through strict QC, wear resistance and high temperature resistance. In addition, there are also have long service life, clear printing effect, solid fixing and no ghosting features.

15 years of brand guarantee quality, 24 hours online, give you 100% satisfaction, choose us and we will provide you with a one-stop consumable service.

█ Material Environmental Protection

█ Exquisite Craftsmanship, Complete Model

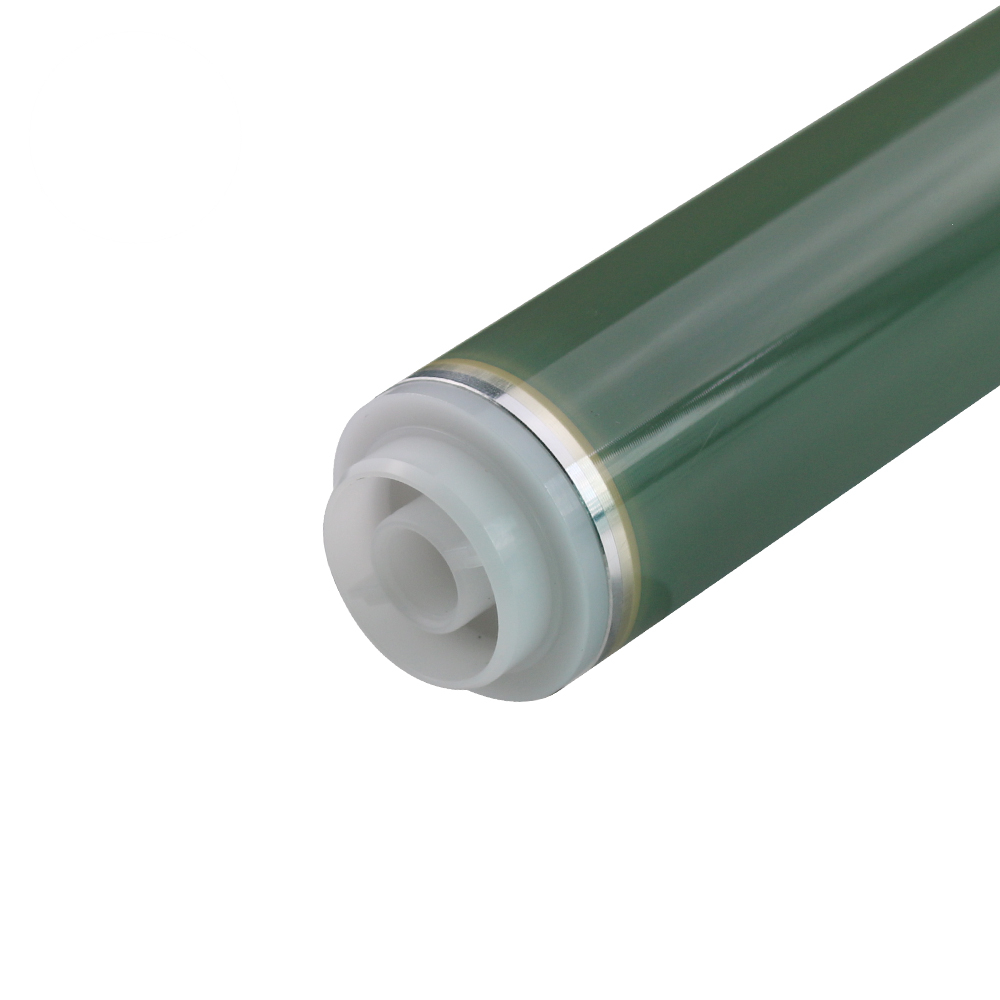

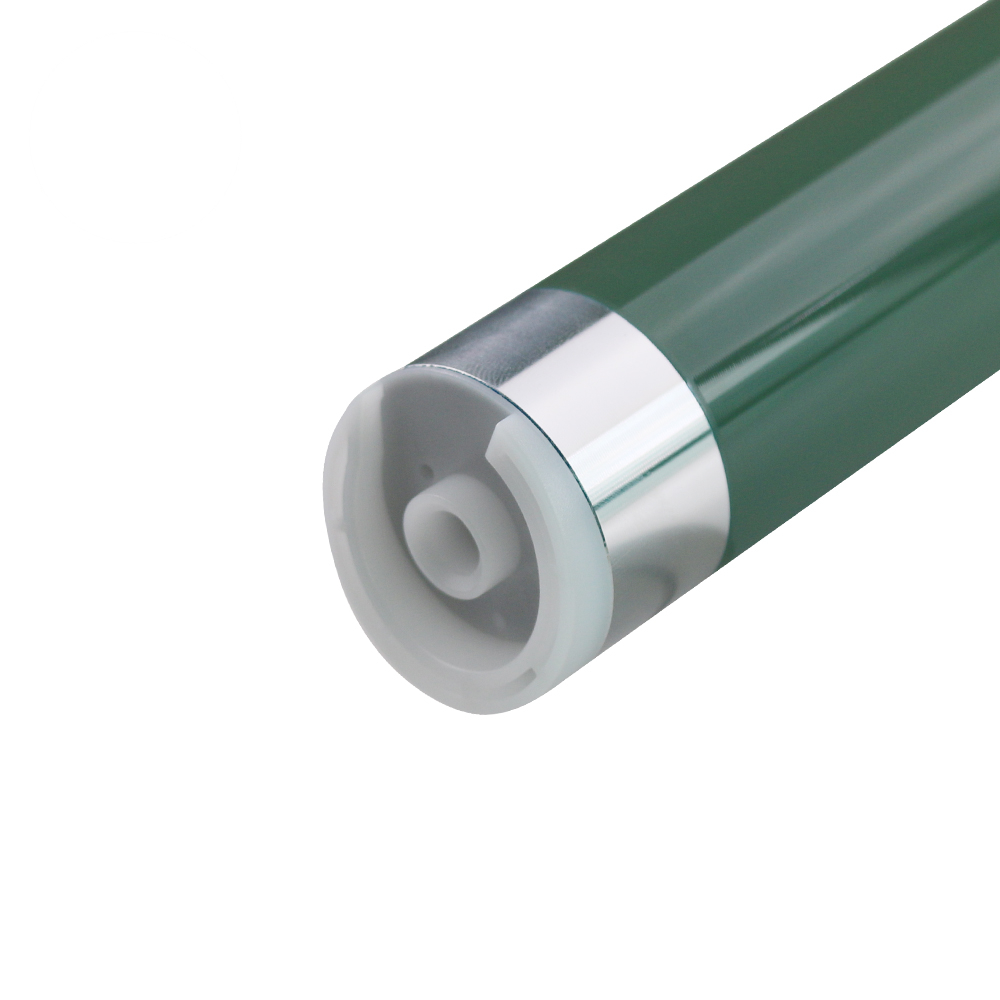

█ Pay Attention To Details, Keep Improving

█ 15 Years Brand, Guaranteed Quality

█ Factory Competitive Price

█ Not To Hurt The Machine

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved